Product > Investigation

Assessment of the depth of carbonation using CARBONTEST® is carried out in a short time and at low cost. Thanks to the simplicity of the test and the lack of the typical difficulties of traditional methods, it can be carried out on every kind of structure.

The patented CARBONTEST® method is the alternative to the current method of investigation. It has introduced a new sampling method, based on collection of powder during a drilling carried out employing an ordinary percussion drill and gathering the powder in a specific device (picker) designed for the following carbonation analysis. This comes with a specially designed software which makes it possible to process the data automatically and evaluate the decay trend of the structure.

CARBONTEST® affords an investigation which is:

- Quick, the estimated time for each test is two minutes.

- Easy, no specific machinery is needed, and it can be carried out by non specialized staff.

- Effective, it accurately and punctually measures the depth of carbonation of the concrete and estimates the working life of the structure.

- Efficient, it can manage the depth of carbonation cutting financial and physical resources down to a minimum.

Thanks to the innovative CARBONTEST® instruments, one can inspect any kind of structure, from residential buildings to hospital facilities, from small items to large infrastructures, without damaging the elements being tested.

PHASES OF THE INVESTIGATION

The CARBONTEST® investigation for measuring the depth of carbonation of a reinforced concrete item is developed over various stages which make it possible to acquire, for each testing point, the information needed to evaluate the evolution of the decay.

PHASE 1 – CHOOSING A TEST POINT Each structure to be analyzed presents some points which are more sensitive than others to carbonation decay. Once the zones which can provide the most significant results have been identified, the test is carried out. The collection device, together with the picker, is placed on the item to be analyzed. |

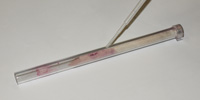

Using an ordinary percussion drill with a masonry tip, the concrete is drilled at a constant speed throughout the operation. The first powder coming out is collected at the bottom of the picker and the last at its top. Use of a transparent container allows to check the regular inflow of powder throughout perforation. The result is an ordered sample of powder inside the picker. |

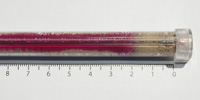

PHASE 3 – MEASURING HOLE AND SAMPLE At the end of the perforation, one must keep the collecting device, complete with its sample in the picker, in a vertical position. Using the ruler with the graded scale, one establishes the exact length of the collected powder sample, and this is compared with the measurement of the actual depth of the hole in the item. |

PHASE 4 – ANALYSIS WITH PHENOLPHTHALEIN Once the measuring has been carried out, the picker is taken out from the collecting device. Using the pipette, take some phenolphthalein from the bottle and lay a thin layer of it along the flared longitudinal cut on the picker so the liquid can penetrate into the powder of the sample. The chemical reaction of the indicator takes place instantly. Carbonatated concrete does not change its colour, while the concrete which has not yet been affected by carbonation takes on a typical magenta red hue. |

PHASE 5 – MEASURING CARBONATION Once the point of passage has been identified between the carbonatated powder and the alkaline powder, the graded scale ruler allows to measure to the millimetre the length of the carbonatated part, distinguishing it from the non degraded part. Comparing the measurement with the scale ratio established during Phase 3, one can calculate the actual value of the depth of the carbonation front at the point of the item being analyzed. |

PHASE 6 – CLOSING THE HOLE At the end of the test, the hole made to carry out the collection is closed. Using the quick drying cement plaster in the CARBONTEST® Kit, the surface is restored. This way, besides bringing back the original appearance of the sampled item, the possibility of aggression by outside agents which could locally accelerate decay are averted. Cleaning the collection device (picker) with an air blow, the residue of powder remaining on the inside walls and on the brush is removed. Put in a new flared picker to carry out a new test at once. |

The investigation sheets in the CARBONTEST® Kit provide excellent support during the investigation for writing down all the measurements which have been made and for drawing up the final technical report. The CARBONTEST® Report Software allows to re-process the data collected during the tests and provides important information for estimating the residual life of the structure.