Carbonation > Diagnostics

Preventing carbonation is the only possible way to prevent the decay of a reinforced concrete structure. Already when planning and building, one must pay attention to structural choices and materials which reduce the development of decay. But carbonation is an inevitable phenomenon, since it also depends on environmental factors. This makes it necessary to schedule continuous inspection and maintenance interventions throughout the service life of the building.

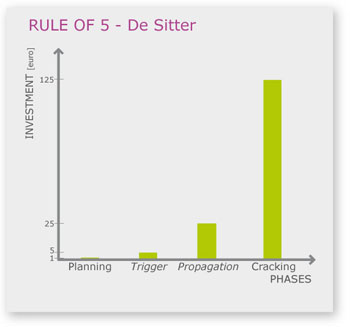

As the decay goes on, costs for restoration work also change, as De Sitter clearly explained in his Rule of 5: “1 Euro spent to get a properly planned and made structure affords the same benefits that could be obtained spending 5 when the construction is finished but the corrosion process is just starting; 25 from the moment when it has started to propagate and 125 when decay and corrosion have led to cracking of the concrete cover over reinforcement”.

As the decay goes on, costs for restoration work also change, as De Sitter clearly explained in his Rule of 5: “1 Euro spent to get a properly planned and made structure affords the same benefits that could be obtained spending 5 when the construction is finished but the corrosion process is just starting; 25 from the moment when it has started to propagate and 125 when decay and corrosion have led to cracking of the concrete cover over reinforcement”.Therefore, it is of fundamental importance to plan periodic diagnostic interventions, so as to find out as much as possible about the evolution, the speed and duration of the decay of the concrete. In order to reduce the resources needed for the restoration work, one must intervene during the initial period, when the carbonation front starts to advance (see graphic of the evolution of carbonation).

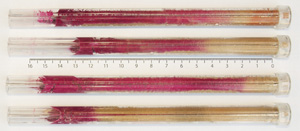

The depth of carbonation can be established using the phenolphthalein test. (Methodology defined by the UNI 9944:1992 standard)

Specimens This procedure makes use of the properties of the reagent which changes colour, turning to magenta red when in contact with concrete having a pH> 8,0÷9,8 and stays colourless for lower values of pH. The depth of carbonation must be established immediately after taking the sample, by spraying the phenolphthalein solution onto the specimen. Carbonatated concrete does not change colour, while concrete which has not yet been reached by carbonation takes on the typical magenta red colour of the reagent in an alkaline environment. In order to estimate the penetration of carbonation in a structure in the best way, the specimens should be taken from a sufficiently wide range of samples.

Specimens This procedure makes use of the properties of the reagent which changes colour, turning to magenta red when in contact with concrete having a pH> 8,0÷9,8 and stays colourless for lower values of pH. The depth of carbonation must be established immediately after taking the sample, by spraying the phenolphthalein solution onto the specimen. Carbonatated concrete does not change colour, while concrete which has not yet been reached by carbonation takes on the typical magenta red colour of the reagent in an alkaline environment. In order to estimate the penetration of carbonation in a structure in the best way, the specimens should be taken from a sufficiently wide range of samples.

Up to the present, unfortunately, it has been quite difficult to assess the evolution of carbonation in a structure in a constant manner, since available methods of analysis are very expensive and need specific materials and equipment, and cannot be effected on every surface of a structure.

Traditional methods |

The standard of reference for the analysis of carbonation calls for the possibility of making the analysis using different methods. The most inexpensive and widely used methodology hitherto used to carry out an investigation on the depth of carbonation is based on the extraction of cylindrical samples (cores), taken by a special machine equipped with drilling tools and a water-cooled diamond tip. Use of this method gives rise to several problems: - Difficulty in carrying out the test In fact, the collection of samples requires relatively expensive equipment which, because of its weight and vibrations, must be attached to the item being analyzed using anchoring dowels. Cooling of the tool usually requires a continuous flow of water, which leads to obvious problems in the case of interventions in inhabited buildings. - High risk of damage to the structure. Since the tool is also able to cut metals, damage to the reinforcement is quite common, and this reduces the bearing capacity of the structure. One must also take into account that the size of the hole to be filled again is between 25÷100 mm. - High test costs. The kind of equipment, the long duration of the extraction and the interventions needed to restore the structure make coring analysis very expensive. - Limits of execution. Because of the many difficulties involved, the core test is carried out only on one point of the building, without a more complete mapping, and only on important structures which have been especially damaged. Other methods call for collecting fragments of concrete*, *if the cover is especially detached from the reinforcement, or the collecting of dust using percussion drills.

|

The innovative |

The innovative CARBONTEST® method for the analysis of the depth of carbonation, in compliance with the standard UNI 9944:1992, overcome the main difficulties associated with traditional methods and permits the execution of numerous sample collections, in a short time and at a low cost, with the possibility of versatile use for every kind of structure.

Use of CARBONTEST® eliminates every difficulty:

|

Carbontest test The CARBONTEST® method involves continuously collecting the powders produced during drilling of a concrete structure, carried out using a common percussion drill with masonry tips. The result of the collection is a sample of powder ordered inside a test tube. In the test tube, which has a thin longitudinal cut, just after the extraction, one lets the alcoholic phenolphthalein solution filter in; the carbonatated concrete does not change its colour, while the concrete which has not yet been reached by carbonation takes on a typical magenta red colour.

Carbontest test The CARBONTEST® method involves continuously collecting the powders produced during drilling of a concrete structure, carried out using a common percussion drill with masonry tips. The result of the collection is a sample of powder ordered inside a test tube. In the test tube, which has a thin longitudinal cut, just after the extraction, one lets the alcoholic phenolphthalein solution filter in; the carbonatated concrete does not change its colour, while the concrete which has not yet been reached by carbonation takes on a typical magenta red colour.